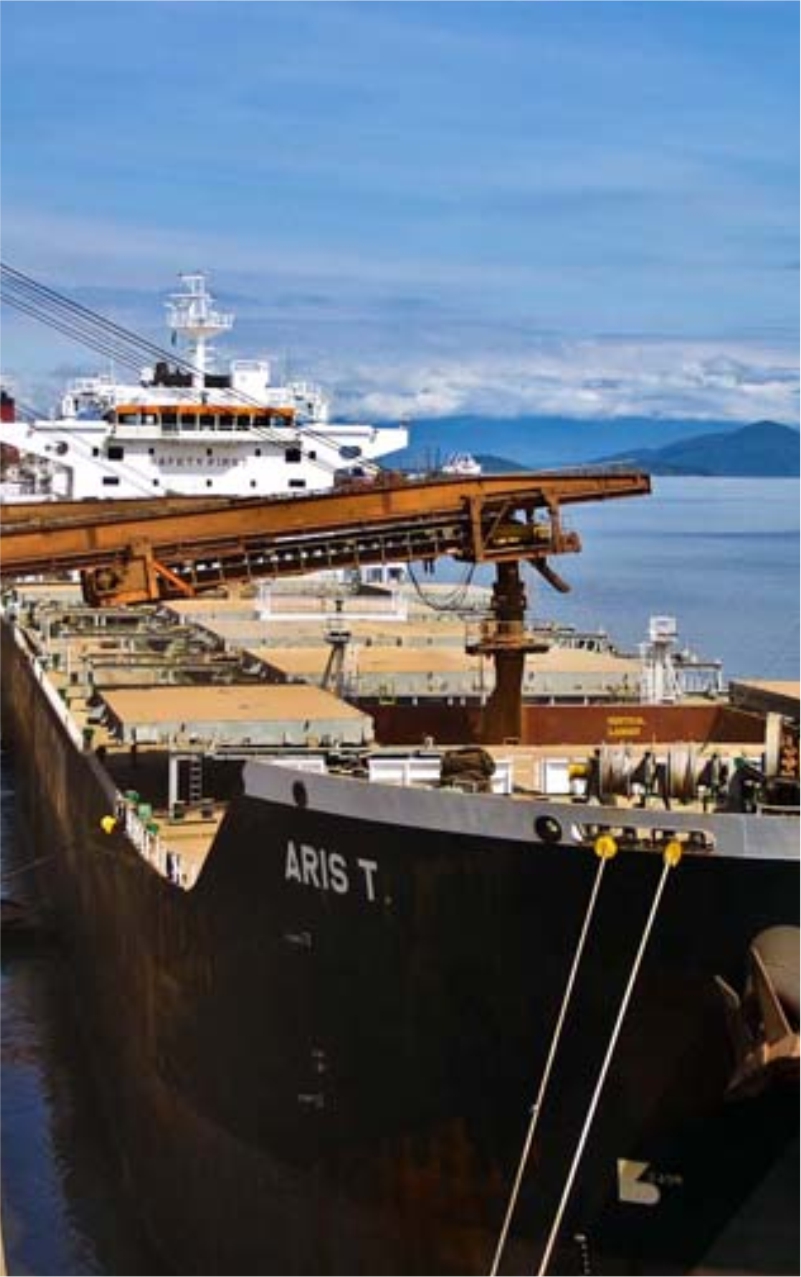

1. REPRESENTATIVE COLLECTION AND SAMPLING ON SHIP

Ports with direct discharge / warehouse: Representative manual collection in the vessel holds and storage cells. In the basements samples should be collected with the aid of a probe, dividing into Top, Middle and Bottom. At each sampling level, 9 samples should be collected, as shown below.

After collection make grouping, homogenization and quarteamento of the samples. From each basement 3 samples should be left, which will later be unified. Thus a vessel with 5 holds should have 5 samples for particle size analysis, moisture, abrasion and hardness.

For chemical analysis, 1 sample per ship.

2. REPRESENTATIVE COLLECTION AND SAMPLING

Sample collection with a cell cut in half, that is, half of the original capacity, following the collection profile of the top base, walking on the pile, collecting with the aid of probe approximately 50 sub-samples.

After the collection, grouping, homogenization and quartetment of the samples to be sent to the laboratory for analysis.

3. CHEMICAL ANALYSIS

The sample must undergo chemical analysis according to the methodology established by A.O.A.C (Association of Analytical Communities - International) and LANARV (National Laboratory of Brazilian Plant Reference).

4. GRANULOMETRIC ANALYSIS

The granulometric analysis should follow the A.O.A.C (Association of Analytical Communities International) methodology using sieves:

• Tyler #5 = 4,0mm

• Tyler #9 = 2,0mm

• Tyler #12 = 1,4mm

• Tyler #16 = 1,0mm

• Tyler #32 = 0,5mm

5. HARDNESS ANALYSIS

Methodology of analysis according to IFDC (International Fertilizer Development Center) using durometer apparatus.

6. ABRASION ANALYSIS

Analysis following IFDC methodology (International Fertilizer Development Center).

7. HUMIDITY ANALYSIS

Analysis based on A.O.A.C (Association of Analytical Communities - International) or LANARV methodology.

8. REPORT

It should be delivered in English / Portuguese containing:

• Accompanying the discharge, problems, equipment, product spillage;

• Visual appearance of the product (raw material quality, amount of powder, product free-flowing condition);

• Reporting of storage conditions;

• Result of physical-chemical analysis.